Aquaponic Automation Systems in 2025: How Smart Technologies Are Transforming Sustainable Agriculture. Explore Market Growth, Innovations, and the Future of Automated Aquaponics.

- Executive Summary: Key Trends and Market Drivers in 2025

- Global Market Size, Segmentation, and 2025–2030 Growth Forecasts

- Core Technologies: Sensors, IoT, and AI in Aquaponic Automation

- Leading Companies and Industry Initiatives (e.g., pentairaes.com, aquaponics.com)

- Case Studies: Commercial Deployments and Success Stories

- Regulatory Landscape and Industry Standards (e.g., aquaponicsassociation.org)

- Investment, Funding, and M&A Activity in Aquaponic Automation

- Challenges: Technical, Economic, and Environmental Barriers

- Future Outlook: Emerging Innovations and Next-Gen Automation (2025–2030)

- Strategic Recommendations for Stakeholders and New Entrants

- Sources & References

Executive Summary: Key Trends and Market Drivers in 2025

Aquaponic automation systems are poised for significant growth and technological advancement in 2025, driven by the convergence of sustainability imperatives, labor shortages, and the maturation of smart agriculture technologies. The integration of sensors, Internet of Things (IoT) platforms, and artificial intelligence (AI) is transforming aquaponic operations, enabling real-time monitoring and precise control of water quality, nutrient dosing, and environmental parameters. This automation not only enhances crop yields and fish health but also reduces operational costs and resource consumption, aligning with global sustainability goals.

Key industry players are accelerating innovation in this space. Autogrow, a New Zealand-based company, continues to expand its suite of automation solutions, offering cloud-connected systems that manage pH, temperature, dissolved oxygen, and nutrient levels. Their platforms are increasingly adopted by commercial growers seeking scalable, data-driven management. Similarly, Priva, headquartered in the Netherlands, is leveraging its expertise in horticultural automation to deliver integrated climate and water management systems tailored for aquaponic facilities. These solutions are designed to optimize resource use and ensure consistent production, even in urban or resource-constrained environments.

The adoption of automation is further propelled by the entry of established greenhouse technology providers into the aquaponics sector. Jain Irrigation Systems, a global leader in precision irrigation, is adapting its sensor and control technologies for aquaponic applications, supporting growers in achieving higher efficiency and traceability. Meanwhile, Grodan, known for its substrate and monitoring solutions, is collaborating with aquaponic farms to integrate real-time data analytics for both plant and fish health.

In 2025, regulatory and market pressures for sustainable food production are expected to intensify, favoring automated aquaponic systems that can demonstrate reduced water and fertilizer usage, lower carbon footprints, and transparent supply chains. Urban agriculture initiatives, particularly in North America, Europe, and parts of Asia, are increasingly incorporating automated aquaponics to meet local food demand and resilience goals.

Looking ahead, the next few years will likely see further convergence of robotics, machine learning, and remote management platforms, making aquaponic automation more accessible to mid-sized and small-scale producers. As costs decline and interoperability improves, the sector is set to play a pivotal role in the evolution of sustainable, technology-driven agriculture.

Global Market Size, Segmentation, and 2025–2030 Growth Forecasts

The global market for aquaponic automation systems is experiencing robust growth as technological advancements and sustainability imperatives drive adoption across commercial and research sectors. As of 2025, the market is characterized by increasing integration of Internet of Things (IoT), artificial intelligence (AI), and sensor-based controls, enabling precise management of water quality, nutrient dosing, and environmental parameters in aquaponic facilities. This automation is critical for optimizing yields, reducing labor costs, and ensuring consistent production, particularly as urban agriculture and controlled environment agriculture (CEA) expand worldwide.

Market segmentation reveals three primary categories: commercial-scale systems, research and educational installations, and small-scale or hobbyist setups. Commercial-scale aquaponic automation is dominated by large greenhouse operators and vertical farming enterprises, who require scalable, reliable, and data-driven solutions. Notable companies such as Autogrow and Priva are recognized for their advanced automation platforms, offering cloud-based monitoring, automated dosing, and climate control tailored for aquaponic environments. Autogrow, for example, provides modular automation systems that integrate with existing infrastructure, supporting both aquaculture and hydroponic components. Priva specializes in climate and process automation, with solutions increasingly adopted in aquaponic greenhouses across Europe and North America.

The research and educational segment is supported by institutions and technology providers such as UrbanFarmers AG, which collaborates with universities and public sector bodies to deploy pilot projects and demonstration systems. These installations often serve as testbeds for new automation technologies and data analytics, contributing to the refinement of commercial offerings.

Regionally, North America and Europe are leading markets, driven by early adoption of CEA and supportive regulatory frameworks. Asia-Pacific is emerging rapidly, particularly in urban centers where land scarcity and food security concerns are acute. Companies like Nelson and Pade, Inc. are expanding their reach in these regions, offering turnkey aquaponic systems with integrated automation for both commercial and institutional clients.

Looking ahead to 2030, the aquaponic automation systems market is projected to maintain double-digit annual growth rates, fueled by increasing investment in sustainable agriculture, urban food production, and climate-resilient farming. The proliferation of smart sensors, machine learning algorithms, and remote management platforms is expected to further reduce operational costs and enhance system scalability. As more governments and private investors prioritize food security and resource efficiency, the demand for advanced aquaponic automation solutions is set to accelerate, with established players and new entrants alike expanding their portfolios to meet diverse market needs.

Core Technologies: Sensors, IoT, and AI in Aquaponic Automation

Aquaponic automation systems are rapidly evolving, driven by the integration of advanced sensors, Internet of Things (IoT) connectivity, and artificial intelligence (AI). As of 2025, these core technologies are enabling more precise, scalable, and sustainable aquaponic operations, addressing both commercial and research needs.

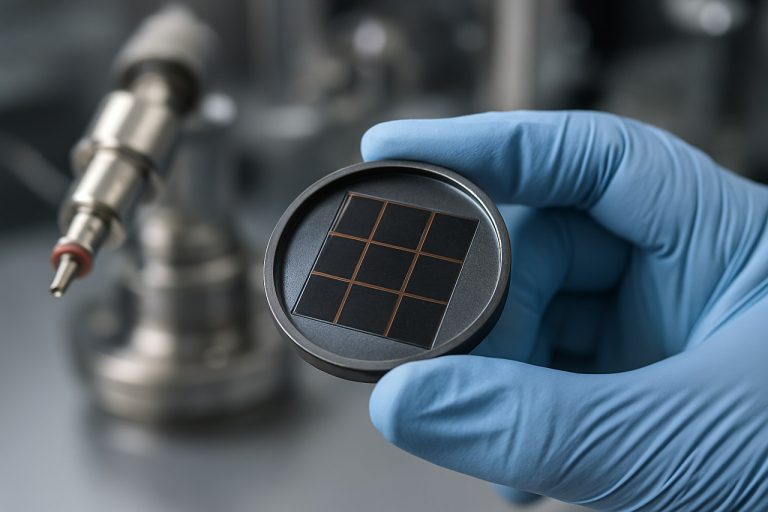

Modern aquaponic systems rely on a network of sensors to monitor critical parameters such as water temperature, pH, dissolved oxygen, ammonia, nitrate levels, and flow rates. Companies like Seneye and Yokogawa Electric Corporation are recognized for their robust water quality monitoring solutions, which are increasingly being adapted for aquaponic applications. These sensors provide real-time data, forming the backbone of automated control systems that can adjust feeding, aeration, and water circulation to maintain optimal conditions for both fish and plants.

IoT platforms are central to the next generation of aquaponic automation. By connecting sensors, actuators, and controllers to cloud-based dashboards, operators can remotely monitor and manage their systems. Autogrow, a global provider of automation technology for controlled environment agriculture, offers IoT-enabled solutions that integrate environmental monitoring, dosing, and alerting functions. Their systems are designed to scale from small urban farms to large commercial facilities, reflecting a broader industry trend toward modular, interoperable automation.

Artificial intelligence is increasingly being leveraged to optimize aquaponic operations. AI algorithms analyze historical and real-time data to predict system needs, automate decision-making, and detect anomalies before they become critical. For example, Priva, a leader in climate and process automation, is developing AI-driven platforms that can dynamically adjust environmental parameters and resource inputs, improving yields and reducing waste. These advancements are expected to become more widespread in the next few years, as machine learning models are trained on larger datasets from diverse aquaponic installations.

Looking ahead, the convergence of sensors, IoT, and AI is set to further transform aquaponic automation. Industry stakeholders anticipate greater interoperability between devices, enhanced predictive analytics, and more user-friendly interfaces. As regulatory and sustainability pressures mount, these technologies will be critical for ensuring compliance, traceability, and resource efficiency. The ongoing innovation from companies like Seneye, Autogrow, Yokogawa Electric Corporation, and Priva will likely shape the sector’s trajectory through 2025 and beyond.

Leading Companies and Industry Initiatives (e.g., pentairaes.com, aquaponics.com)

The aquaponic automation systems sector is experiencing rapid evolution in 2025, driven by the convergence of precision agriculture, IoT, and sustainable food production. Several leading companies are at the forefront, developing integrated solutions that automate water quality monitoring, nutrient dosing, environmental control, and data analytics for both commercial and educational aquaponic operations.

One of the most prominent players is Pentair, a global water treatment and sustainable solutions provider. Pentair’s Aquatic Eco-Systems division offers a suite of automation products, including sensors, controllers, and cloud-based management platforms tailored for aquaponics. Their systems enable real-time monitoring and automated adjustment of pH, dissolved oxygen, temperature, and ammonia levels, helping operators optimize fish and plant health while reducing labor and resource use. In 2024 and 2025, Pentair has expanded its offerings with more modular, scalable automation kits, targeting both large-scale commercial farms and smaller educational or research installations.

Another key industry leader is The Aquaponic Source, which specializes in turnkey aquaponic systems and automation solutions for hobbyists, schools, and commercial growers. Their product line includes automated dosing systems, environmental sensors, and remote monitoring tools. In 2025, The Aquaponic Source is focusing on user-friendly interfaces and plug-and-play automation modules, aiming to lower the technical barrier for new entrants and support the growing trend of urban and community-based aquaponics.

In Europe, Priva is recognized for its advanced climate and process automation technologies, widely adopted in controlled environment agriculture. Priva’s solutions integrate seamlessly with aquaponic systems, offering centralized control of lighting, humidity, CO2, and irrigation. Their cloud-based platforms allow for predictive analytics and remote management, which are increasingly important as commercial aquaponic farms scale up and diversify their operations.

Industry initiatives are also being driven by organizations such as Aquaponics Association, which promotes best practices, standardization, and knowledge sharing around automation and system integration. Collaborative projects between technology providers and research institutions are expected to accelerate in the next few years, focusing on AI-driven optimization, energy efficiency, and integration with renewable energy sources.

Looking ahead, the outlook for aquaponic automation systems is robust. As the sector matures, leading companies are expected to further enhance interoperability, data-driven management, and sustainability, supporting the global expansion of aquaponics as a resilient food production method.

Case Studies: Commercial Deployments and Success Stories

In recent years, commercial aquaponic operations have increasingly adopted automation systems to optimize resource use, improve yields, and reduce labor costs. As of 2025, several notable case studies highlight the transformative impact of automation in this sector, with a focus on integrated sensor networks, data-driven management, and scalable control platforms.

One prominent example is Priva, a Dutch company specializing in climate and process automation for horticulture and indoor farming. Priva’s automation solutions have been deployed in large-scale aquaponic facilities across Europe and North America, enabling real-time monitoring and control of water quality, nutrient dosing, and environmental parameters. Their systems integrate with cloud-based platforms, allowing operators to remotely manage multiple sites and receive predictive maintenance alerts, which has led to measurable reductions in water and energy consumption.

In the United States, Autogrow has partnered with commercial aquaponic farms to implement modular automation systems that monitor pH, dissolved oxygen, temperature, and ammonia levels. These deployments have demonstrated up to 30% improvements in crop yield consistency and a significant reduction in manual intervention. Autogrow’s open API also allows integration with third-party farm management software, supporting data-driven decision-making and traceability.

Another success story comes from Urban Crop Solutions, a Belgian company that provides turnkey automated vertical farming systems, including aquaponics modules. Their installations in Asia and the Middle East have shown that automation can enable year-round production in challenging climates, with remote diagnostics and AI-driven optimization routines. Urban Crop Solutions reports that their clients have achieved up to 90% water savings compared to conventional agriculture, while maintaining high fish and plant health standards.

Looking ahead, the outlook for aquaponic automation is robust. Industry leaders are investing in advanced sensor technologies, machine learning algorithms for predictive crop management, and IoT-enabled platforms for seamless integration. As regulatory frameworks evolve and sustainability targets tighten, commercial operators are expected to further embrace automation to ensure compliance and profitability. The next few years will likely see broader adoption of fully autonomous systems, with real-time analytics and adaptive controls becoming standard features in commercial aquaponic deployments.

Regulatory Landscape and Industry Standards (e.g., aquaponicsassociation.org)

The regulatory landscape for aquaponic automation systems is evolving rapidly as the sector matures and technology adoption accelerates. In 2025, industry stakeholders are witnessing increased attention from both governmental agencies and industry associations, aiming to establish clear standards for system safety, environmental impact, and food quality. The Aquaponics Association continues to play a pivotal role in advocating for best practices and providing guidance on compliance, particularly as automation introduces new complexities in monitoring, data management, and system control.

Automation in aquaponics—encompassing sensors, IoT devices, and AI-driven management platforms—has prompted regulators to consider new frameworks for data integrity, traceability, and biosecurity. In the United States, the Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA) are increasingly engaging with industry groups to ensure that automated aquaponic operations meet food safety standards, especially under the Food Safety Modernization Act (FSMA). Automated systems must demonstrate reliable monitoring of water quality, nutrient levels, and fish health, with data logging and remote alert capabilities becoming de facto requirements for commercial-scale operations.

Industry standards are also being shaped by leading automation technology providers. Companies such as Autogrow and Priva are actively involved in developing interoperable solutions that align with emerging regulatory expectations. These firms are collaborating with growers and industry bodies to ensure that their platforms support compliance, including secure data storage, audit trails, and integration with third-party certification schemes. For example, Autogrow offers cloud-based control systems that facilitate real-time compliance reporting, while Priva focuses on scalable automation for both water and nutrient management.

Looking ahead, the next few years are expected to bring further harmonization of standards, particularly as international trade in aquaponically grown produce expands. The Aquaponics Association is working with global partners to develop certification frameworks that address automation-specific risks and opportunities, such as cybersecurity for remote-controlled systems and standardized protocols for sensor calibration. As automation becomes integral to commercial aquaponics, adherence to robust regulatory and industry standards will be essential for market access, consumer trust, and operational resilience.

Investment, Funding, and M&A Activity in Aquaponic Automation

Investment, funding, and M&A activity in aquaponic automation systems have accelerated in 2025, reflecting the sector’s maturation and the growing demand for sustainable, technology-driven food production. The convergence of aquaculture and hydroponics, enhanced by automation, has attracted both agri-tech investors and established agricultural technology companies seeking to expand their portfolios.

A notable trend in 2025 is the influx of venture capital and strategic investments into companies specializing in integrated automation solutions for aquaponics. Firms such as Autogrow, a New Zealand-based provider of automation and control systems for controlled environment agriculture, have reported increased interest from both institutional investors and agri-tech accelerators. Autogrow’s modular platforms, which monitor and automate nutrient dosing, pH, temperature, and environmental parameters, have positioned the company as a key player in the sector.

Similarly, Priva, a Dutch company with a global footprint in climate and process automation for horticulture, has expanded its aquaponic automation offerings through partnerships and targeted acquisitions. In 2025, Priva’s investment in R&D and collaboration with aquaponic farm operators has led to the development of advanced sensor networks and AI-driven management platforms, further solidifying its market position.

On the North American front, American Hydroponics (AmHydro) has continued to attract funding for its integrated aquaponic automation systems, which are now being deployed in commercial-scale facilities across the United States and Canada. AmHydro’s focus on scalable, turnkey solutions has made it a preferred partner for both new entrants and established growers transitioning to automated aquaponic production.

Mergers and acquisitions have also shaped the competitive landscape. In early 2025, several mid-sized automation technology providers have been acquired by larger agri-tech conglomerates seeking to consolidate expertise and expand their reach in the aquaponics sector. This consolidation is expected to drive further innovation and reduce costs through economies of scale.

Looking ahead, industry analysts anticipate continued growth in investment and M&A activity as automation becomes integral to the economic viability of aquaponic farming. The sector’s outlook is buoyed by increasing consumer demand for sustainably produced food, government incentives for resource-efficient agriculture, and the ongoing digital transformation of the agri-food industry. As automation technologies become more sophisticated and accessible, the aquaponic automation market is poised for robust expansion through 2025 and beyond.

Challenges: Technical, Economic, and Environmental Barriers

Aquaponic automation systems, while promising for sustainable food production, face a range of technical, economic, and environmental challenges as of 2025 and looking ahead. Technically, the integration of sensors, controllers, and software platforms remains complex. Many systems require precise calibration to monitor water quality parameters such as pH, dissolved oxygen, ammonia, and temperature. Inconsistent sensor accuracy and the need for regular maintenance can lead to system failures or suboptimal plant and fish health. Companies like Autogrow and Priva have developed advanced automation solutions, but widespread adoption is hindered by the need for skilled operators and the lack of standardized protocols across different aquaponic setups.

Economically, the initial investment in automation technology remains a significant barrier, especially for small and medium-sized enterprises. The cost of high-quality sensors, control units, and data management platforms can be prohibitive. While automation can reduce labor costs and improve yields over time, the return on investment is not always immediate. This is particularly challenging in regions where access to capital or technical support is limited. Companies such as Grodan and HortiMaX (a part of Ridder) offer scalable solutions, but affordability and financing options are ongoing concerns for many growers.

From an environmental perspective, automation systems can optimize resource use, but they also introduce new challenges. The production and disposal of electronic components contribute to e-waste, and the energy demands of continuous monitoring and control systems can offset some of the sustainability gains of aquaponics. Furthermore, the reliance on cloud-based data storage and remote monitoring platforms, as provided by companies like Priva, raises questions about data security and the carbon footprint of digital infrastructure.

Looking forward, the sector is expected to address these barriers through increased standardization, modular system designs, and the integration of artificial intelligence for predictive maintenance and optimization. Industry bodies and technology providers are collaborating to develop open-source protocols and training programs to lower the technical threshold for adoption. However, the pace of overcoming these challenges will depend on continued investment, regulatory support, and the demonstration of clear economic and environmental benefits at scale.

Future Outlook: Emerging Innovations and Next-Gen Automation (2025–2030)

The period from 2025 onward is poised to witness significant advancements in aquaponic automation systems, driven by the convergence of smart agriculture, Internet of Things (IoT), and artificial intelligence (AI). As global demand for sustainable food production intensifies, aquaponic operators are increasingly adopting next-generation automation to optimize resource use, reduce labor, and enhance yields.

Key industry players are investing in integrated sensor networks and cloud-based management platforms. For example, Autogrow, a New Zealand-based company, continues to develop modular automation solutions that monitor and control water quality, nutrient dosing, and environmental parameters in real time. Their systems leverage machine learning algorithms to predict plant and fish health trends, enabling proactive interventions and minimizing system downtime.

Similarly, Priva, a Dutch leader in climate and process automation, is expanding its portfolio to include aquaponic-specific modules. These solutions integrate with existing greenhouse management systems, allowing seamless control over temperature, humidity, CO2 levels, and lighting, all tailored to the unique requirements of aquaponic ecosystems. Priva’s open platform approach facilitates interoperability with third-party sensors and actuators, supporting the trend toward fully connected, data-driven farms.

In the United States, Grodan—known for its substrate and precision growing technologies—has begun collaborating with aquaponic farms to adapt its sensor suites and data analytics tools for closed-loop water and nutrient management. This partnership model is expected to accelerate the adoption of precision automation in commercial-scale aquaponics, particularly as regulatory pressures on water use and food safety increase.

Looking ahead to 2030, the integration of robotics for tasks such as automated harvesting, fish feeding, and system cleaning is anticipated to become more widespread. Companies like Autogrow and Priva are already piloting robotic modules that can be retrofitted into existing systems, reducing manual labor and improving operational consistency.

The outlook for aquaponic automation is further bolstered by the emergence of open-source hardware and software platforms, which lower entry barriers for small and medium-sized producers. Industry bodies and technology alliances are expected to play a pivotal role in standardizing protocols and ensuring interoperability across devices, fostering a more robust and scalable ecosystem for automated aquaponics in the years ahead.

Strategic Recommendations for Stakeholders and New Entrants

As aquaponic automation systems continue to evolve rapidly in 2025, stakeholders and new entrants must adopt strategic approaches to capitalize on emerging opportunities and address sector-specific challenges. The integration of advanced sensors, IoT connectivity, and AI-driven analytics is transforming operational efficiency, crop yield optimization, and resource management in aquaponics. Below are key recommendations for various stakeholders:

- Invest in Modular and Scalable Solutions: New entrants should prioritize modular automation platforms that allow for incremental expansion. Companies like Autogrow and Priva offer scalable control systems that can be tailored to both small-scale startups and large commercial facilities, enabling flexibility as operations grow.

- Leverage Data-Driven Decision Making: Stakeholders should implement systems that collect and analyze real-time data on water quality, nutrient levels, and environmental conditions. Autogrow and Priva provide cloud-based platforms that facilitate remote monitoring and predictive analytics, supporting proactive management and reducing labor costs.

- Prioritize Interoperability and Open Standards: As the sector matures, interoperability between automation components and legacy systems becomes critical. Engaging with suppliers that support open protocols ensures future-proofing and easier integration of new technologies.

- Focus on Sustainability and Resource Efficiency: Automation should be leveraged to minimize water and energy consumption, aligning with global sustainability goals. Companies like Pentair Aquatic Eco-Systems are developing energy-efficient pumps and filtration systems that can be integrated into automated aquaponic setups, supporting both environmental and economic objectives.

- Engage in Strategic Partnerships: Collaborations with technology providers, research institutions, and established growers can accelerate innovation and market entry. For example, Autogrow has partnered with universities and commercial farms to pilot new automation technologies, providing valuable field data and validation.

- Stay Informed on Regulatory Developments: Automation systems must comply with evolving food safety and environmental regulations. Stakeholders should monitor updates from industry bodies and government agencies to ensure compliance and leverage certifications as a market differentiator.

Looking ahead, the aquaponic automation sector is expected to see increased adoption of AI and machine learning for predictive maintenance and autonomous system optimization. Stakeholders who invest early in adaptable, data-centric automation platforms and foster collaborative networks will be best positioned to lead in this dynamic market.