Half-Life Isotope Radiopharmaceuticals Manufacturing in 2025: Innovations, Market Expansion, and the Next Era of Precision Medicine. Discover How Advanced Production and Regulatory Shifts Are Shaping the Industry’s Future.

- Executive Summary: 2025 Market Overview and Key Insights

- Industry Landscape: Major Players and Value Chain Analysis

- Market Size, Segmentation, and 2025–2029 Growth Forecasts

- Technological Innovations in Isotope Production and Purification

- Regulatory Environment and Compliance Trends

- Supply Chain Dynamics and Raw Material Sourcing

- Emerging Applications in Oncology, Cardiology, and Neurology

- Regional Analysis: North America, Europe, Asia-Pacific, and Rest of World

- Competitive Strategies and Partnership Developments

- Future Outlook: Disruptive Technologies and Market Opportunities

- Sources & References

Executive Summary: 2025 Market Overview and Key Insights

The global landscape for half-life isotope radiopharmaceuticals manufacturing is undergoing significant transformation in 2025, driven by advances in nuclear medicine, increasing demand for precision diagnostics and therapeutics, and evolving regulatory frameworks. Radiopharmaceuticals, which utilize isotopes with varying half-lives, are essential for both diagnostic imaging (such as PET and SPECT scans) and targeted radiotherapy. The market is characterized by a growing emphasis on short-lived isotopes, such as Fluorine-18 and Gallium-68, due to their clinical utility and logistical challenges associated with their rapid decay.

Key industry players are expanding their production capacities and distribution networks to meet rising global demand. Curium, a leading radiopharmaceutical manufacturer, continues to invest in new cyclotron and generator technologies to enhance the supply of short half-life isotopes. Similarly, Cardinal Health maintains a robust network of nuclear pharmacies and distribution centers, ensuring timely delivery of radiopharmaceuticals across North America. Siemens Healthineers and GE HealthCare are also notable for their integrated solutions, combining isotope production with advanced imaging systems and workflow optimization.

In 2025, regulatory agencies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) are streamlining approval processes for novel radiopharmaceuticals, particularly those utilizing isotopes with ultra-short half-lives. This regulatory support is fostering innovation and accelerating the introduction of new diagnostic and therapeutic agents. The expansion of theranostics—combining diagnostic imaging and targeted therapy—continues to drive demand for isotopes like Lutetium-177 and Actinium-225, with companies such as Nordion and ITT (through its subsidiary ITM Isotope Technologies Munich) playing pivotal roles in supply chain development.

Supply chain resilience remains a top priority, as the industry addresses challenges related to isotope production, transportation, and regulatory compliance. Strategic partnerships and investments in local production facilities are mitigating risks associated with international logistics and geopolitical uncertainties. The outlook for the next few years points to continued growth, with increased adoption of radiopharmaceuticals in oncology, cardiology, and neurology, as well as ongoing research into novel isotopes and production methods.

- Expansion of cyclotron and generator infrastructure by major manufacturers.

- Regulatory acceleration for new radiopharmaceutical approvals.

- Growth in theranostic applications and targeted therapies.

- Focus on supply chain robustness and local production capabilities.

Overall, the half-life isotope radiopharmaceuticals manufacturing sector in 2025 is marked by innovation, collaboration, and a strong outlook for sustained growth, underpinned by the efforts of leading industry players and supportive regulatory environments.

Industry Landscape: Major Players and Value Chain Analysis

The half-life isotope radiopharmaceuticals manufacturing sector is a highly specialized segment of the broader nuclear medicine industry, characterized by stringent regulatory oversight, complex logistics, and a concentrated group of major players. As of 2025, the industry is shaped by a handful of multinational corporations, state-owned enterprises, and specialized radiopharmaceutical manufacturers, each playing a critical role across the value chain—from isotope production to radiopharmaceutical formulation and distribution.

At the upstream end, the production of medical isotopes such as technetium-99m (Tc-99m), fluorine-18 (F-18), and lutetium-177 (Lu-177) is dominated by a few large-scale nuclear reactors and cyclotron facilities. Nordion, a subsidiary of Sotera Health, is a leading global supplier of Cobalt-60 and other medical isotopes, leveraging decades of reactor-based production expertise. In Europe, Curium stands out as a vertically integrated leader, operating both reactors and processing facilities, and supplying a broad portfolio of SPECT and PET isotopes. Ion Beam Applications (IBA) is a key cyclotron manufacturer and operator, supporting the growing demand for short half-life PET isotopes like F-18.

Midstream, the formulation and compounding of radiopharmaceuticals is handled by specialized manufacturers and radiopharmacies. Cardinal Health operates one of the largest radiopharmacy networks in the United States, providing daily delivery of patient-ready doses to hospitals and imaging centers. Siemens Healthineers and GE HealthCare are also significant players, not only supplying radiopharmaceuticals but also developing the imaging equipment and software that utilize these agents.

Downstream, the distribution of radiopharmaceuticals is a logistical challenge due to the short half-lives of many isotopes. Companies like Curium and Cardinal Health have developed sophisticated cold chain logistics and just-in-time delivery systems to ensure product efficacy and patient safety. In addition, Nordion and IBA are investing in decentralized production models, such as compact cyclotrons and generator systems, to bring isotope manufacturing closer to the point of care.

Looking ahead, the industry is expected to see increased investment in alternative production technologies, such as non-reactor-based methods for Mo-99 and the expansion of cyclotron networks for PET isotopes. Strategic partnerships, vertical integration, and regulatory harmonization will likely shape the competitive landscape, as major players seek to secure supply chains and meet the rising global demand for advanced diagnostic and therapeutic radiopharmaceuticals.

Market Size, Segmentation, and 2025–2029 Growth Forecasts

The global market for half-life isotope radiopharmaceuticals manufacturing is poised for robust growth between 2025 and 2029, driven by expanding clinical applications, technological advancements, and increasing investments in nuclear medicine infrastructure. Radiopharmaceuticals with both short and medium half-lives—such as technetium-99m, fluorine-18, gallium-68, and lutetium-177—are central to diagnostic imaging and targeted therapies, particularly in oncology, cardiology, and neurology.

Market segmentation is typically based on isotope half-life (short, medium, long), application (diagnostic vs. therapeutic), and end-user (hospitals, diagnostic centers, research institutes). Short half-life isotopes, such as fluorine-18 (t½ ≈ 110 min) and technetium-99m (t½ ≈ 6 h), dominate the diagnostic segment due to their widespread use in PET and SPECT imaging. Medium and longer half-life isotopes, including lutetium-177 (t½ ≈ 6.7 d) and iodine-131 (t½ ≈ 8 d), are increasingly used in targeted radionuclide therapies.

Key manufacturers and suppliers are expanding their production capacities and distribution networks to meet rising demand. Curium, a global leader in nuclear medicine, operates multiple production sites across Europe and North America, focusing on both SPECT and PET isotopes. Cardinal Health is a major supplier in the U.S., providing a broad portfolio of radiopharmaceuticals and operating one of the largest radiopharmacy networks. Siemens Healthineers and GE HealthCare are also significant players, not only supplying isotopes but also developing cyclotrons and automated synthesis platforms to streamline on-site production.

The market outlook for 2025–2029 is shaped by several factors:

- Rising incidence of cancer and cardiovascular diseases, fueling demand for both diagnostic and therapeutic radiopharmaceuticals.

- Expansion of cyclotron and reactor infrastructure, particularly in Asia-Pacific and North America, to address supply chain vulnerabilities and reduce reliance on aging nuclear reactors.

- Regulatory support and public-private partnerships, such as those seen in the U.S. and Europe, to ensure stable isotope supply and encourage domestic manufacturing.

- Emergence of novel isotopes (e.g., copper-64, actinium-225) and theranostic agents, broadening the clinical utility and market potential.

Overall, the half-life isotope radiopharmaceuticals manufacturing sector is expected to experience high single-digit to low double-digit annual growth rates through 2029, with leading companies investing in new production technologies, logistics, and regulatory compliance to capture expanding global demand.

Technological Innovations in Isotope Production and Purification

The manufacturing of half-life isotope radiopharmaceuticals is undergoing significant technological transformation as the sector adapts to growing clinical demand, regulatory scrutiny, and the need for more efficient, sustainable production. In 2025 and the coming years, several key innovations are shaping the landscape, particularly in the production and purification of short- and medium-lived isotopes such as Fluorine-18, Gallium-68, Lutetium-177, and Actinium-225.

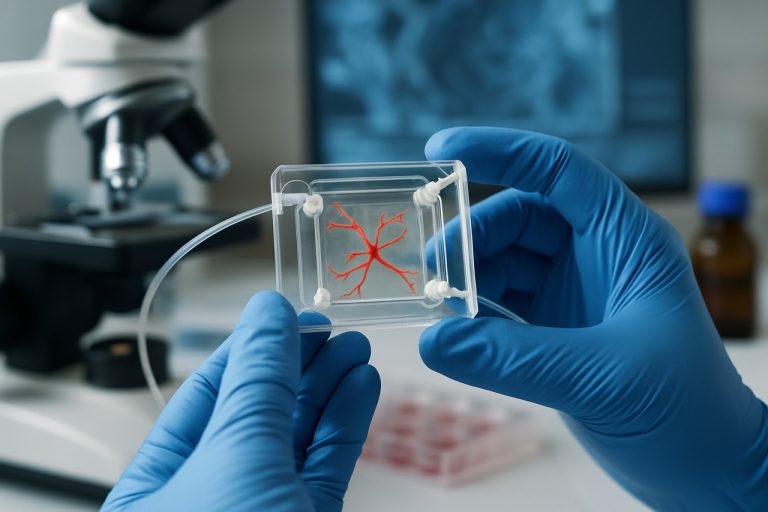

Cyclotron and generator technologies remain at the core of isotope production. Companies like GE HealthCare and Siemens Healthineers are advancing compact, automated cyclotron systems that enable decentralized, on-demand production of PET isotopes, reducing reliance on centralized facilities and mitigating supply chain risks. These systems are increasingly integrated with automated synthesis modules, streamlining the transition from isotope production to radiopharmaceutical formulation.

For generator-produced isotopes, such as Gallium-68, manufacturers including Eckert & Ziegler and ITM Isotope Technologies Munich are introducing next-generation generators with improved elution efficiency, longer shelf life, and enhanced shielding. These advances are critical for expanding access to theranostic agents in both developed and emerging markets.

Purification technologies are also evolving. Automated cassette-based purification systems, such as those developed by TRIUMF and Curium, are being adopted to ensure high radiochemical purity and reproducibility, while minimizing operator exposure. Innovations in solid-phase extraction and microfluidic purification are enabling faster, more selective separation of isotopes from target materials and contaminants, which is particularly important for high-specific-activity products like Actinium-225.

The supply of critical isotopes is being bolstered by investments in new production facilities and partnerships. Nordion and Bruce Power are collaborating to expand reactor-based production of medical isotopes in North America, while ITM Isotope Technologies Munich is scaling up its global network for Lutetium-177 and other therapeutic isotopes. These efforts are supported by digital platforms for real-time tracking and quality assurance, further enhancing reliability and regulatory compliance.

Looking ahead, the integration of artificial intelligence and advanced analytics into production workflows is expected to optimize yield, reduce waste, and accelerate batch release. As regulatory agencies encourage adoption of advanced manufacturing technologies, the sector is poised for continued innovation, with a focus on sustainability, scalability, and patient access.

Regulatory Environment and Compliance Trends

The regulatory environment for half-life isotope radiopharmaceuticals manufacturing is evolving rapidly in 2025, driven by advances in radiochemistry, increasing clinical demand, and the need for harmonized global standards. Regulatory agencies such as the U.S. Food and Drug Administration (FDA), the European Medicines Agency (EMA), and the International Atomic Energy Agency (IAEA) are intensifying oversight to ensure product safety, efficacy, and traceability, particularly as new short-lived isotopes and theranostic agents enter clinical use.

A key trend is the refinement of Good Manufacturing Practice (GMP) requirements specific to radiopharmaceuticals. The FDA has updated guidance to address the unique challenges of short half-life isotopes, emphasizing rapid quality control, sterility assurance, and real-time batch release protocols. The EMA, through its Committee for Medicinal Products for Human Use (CHMP), is similarly updating its guidelines to streamline approval pathways for novel radiopharmaceuticals, including those based on alpha and beta emitters. These changes are designed to reduce time-to-market for critical diagnostics and therapies while maintaining rigorous safety standards.

Manufacturers such as Curium, a global leader in nuclear medicine, and Siemens Healthineers, which operates cyclotron and radiopharmacy networks, are investing in compliance infrastructure and digital quality management systems. These investments support real-time documentation, electronic batch records, and automated deviation tracking, which are increasingly required by regulators. Curium has also been active in collaborating with regulatory bodies to pilot new inspection models that accommodate the rapid production cycles of short-lived isotopes.

Another significant development is the push for harmonization of regulations across regions. The IAEA is facilitating international workshops and technical documents to align standards for isotope production, transport, and waste management. This is particularly important for isotopes with ultra-short half-lives, such as fluorine-18 and gallium-68, which require coordinated logistics and regulatory approvals for cross-border distribution.

Looking ahead, the regulatory outlook for 2025 and beyond includes the anticipated adoption of digital batch release and blockchain-based traceability systems, which are being piloted by major suppliers like GE HealthCare. These technologies promise to enhance transparency and compliance, especially as personalized radiopharmaceuticals and decentralized production models gain traction. The sector is also preparing for stricter environmental and radiation safety regulations, with agencies expected to introduce new requirements for waste minimization and staff exposure monitoring.

In summary, the regulatory landscape for half-life isotope radiopharmaceuticals manufacturing in 2025 is characterized by stricter, more agile compliance frameworks, increased digitalization, and a strong drive toward global harmonization, all aimed at supporting innovation while safeguarding patient and worker safety.

Supply Chain Dynamics and Raw Material Sourcing

The supply chain for half-life isotope radiopharmaceuticals is uniquely complex, shaped by the short-lived nature of many medical isotopes and the stringent regulatory environment. In 2025, the sector is experiencing both persistent challenges and innovative responses, particularly in the sourcing and timely delivery of raw materials such as enriched target materials (e.g., molybdenum-98/100, xenon-124, and cyclotron-grade targets), as well as the logistics of rapid distribution.

A critical bottleneck remains the global reliance on a limited number of nuclear reactors and cyclotrons for the production of key isotopes. For example, the supply of molybdenum-99 (Mo-99), the parent isotope for technetium-99m (Tc-99m), is still concentrated among a handful of reactors in Canada, Europe, and Australia. Companies like Nordion (Canada), NRG (Netherlands), and ANSTO (Australia) are central to this supply chain, providing irradiated targets and processing services for global distribution. The shutdown of aging reactors and scheduled maintenance outages continue to pose risks of supply interruptions, prompting increased investment in alternative production methods, such as accelerator-based and non-reactor technologies.

Raw material sourcing is further complicated by the need for highly enriched and purified target materials. Suppliers such as Eckert & Ziegler and Cambridge Isotope Laboratories provide enriched stable isotopes and custom targets for cyclotron and reactor irradiation. The procurement of these materials is subject to international regulations, export controls, and, in some cases, geopolitical tensions, which can impact lead times and costs.

To mitigate these risks, manufacturers are diversifying their supplier base and investing in vertical integration. For instance, Curium and Lantheus have expanded their in-house capabilities for isotope processing and generator manufacturing, reducing dependency on external suppliers. Additionally, partnerships between isotope producers and radiopharmaceutical companies are becoming more common, aiming to secure long-term contracts and ensure a stable flow of raw materials.

Logistics remain a critical factor due to the short half-lives of many isotopes. Companies are optimizing cold-chain distribution networks and leveraging just-in-time manufacturing to minimize decay losses. The adoption of digital tracking and real-time monitoring technologies is enhancing transparency and reliability across the supply chain.

Looking ahead, the sector is expected to see further investment in domestic isotope production facilities, particularly in North America and Europe, to enhance supply security. The development of new reactor and accelerator projects, as well as the scaling of alternative production methods, will likely reshape the raw material sourcing landscape over the next few years.

Emerging Applications in Oncology, Cardiology, and Neurology

The manufacturing of half-life isotope radiopharmaceuticals is experiencing significant advancements in 2025, driven by the expanding clinical applications in oncology, cardiology, and neurology. These radiopharmaceuticals, which utilize isotopes with varying half-lives, are essential for both diagnostic imaging and targeted radiotherapy. The sector is characterized by rapid innovation, increased production capacity, and a focus on regulatory compliance to meet the growing global demand.

In oncology, the use of short and medium half-life isotopes such as 68Ga, 177Lu, and 225Ac is accelerating. Curium, a leading global radiopharmaceutical manufacturer, has expanded its production of 177Lu, which is widely used in targeted radionuclide therapy for neuroendocrine tumors and prostate cancer. Similarly, Nordion and Eckert & Ziegler are investing in new facilities and partnerships to ensure a stable supply of therapeutic isotopes, addressing previous shortages and supporting the increasing number of clinical trials and commercial therapies.

Cardiology continues to rely on isotopes such as 99mTc and 82Rb for myocardial perfusion imaging. Lantheus remains a key supplier of 99mTc generators, while also advancing the production of 82Rb, which is used in PET imaging for cardiac assessments. The company’s investments in automated manufacturing and distribution logistics are aimed at improving the reliability and accessibility of these critical diagnostics, especially in regions with limited infrastructure.

In neurology, the demand for PET tracers such as 18F-FDG and novel amyloid imaging agents is rising, driven by the increasing prevalence of neurodegenerative diseases. GE HealthCare and Siemens Healthineers are at the forefront of developing and manufacturing these radiopharmaceuticals, leveraging their global cyclotron networks and automated synthesis platforms. These companies are also collaborating with academic and clinical partners to accelerate the translation of new tracers from research to clinical practice.

Looking ahead, the outlook for half-life isotope radiopharmaceutical manufacturing is robust. Industry leaders are investing in next-generation production technologies, such as solid targetry and advanced automation, to enhance yield and purity. Regulatory agencies are also streamlining approval pathways for novel isotopes, facilitating faster adoption in clinical settings. As a result, the sector is poised for continued growth, with a strong emphasis on expanding access to advanced diagnostics and therapies across oncology, cardiology, and neurology.

Regional Analysis: North America, Europe, Asia-Pacific, and Rest of World

The manufacturing landscape for half-life isotope radiopharmaceuticals is evolving rapidly across North America, Europe, Asia-Pacific, and the Rest of World, driven by technological advancements, regulatory changes, and expanding clinical applications. In 2025 and the coming years, regional dynamics are expected to shape both production capacity and innovation trajectories.

North America remains a global leader, underpinned by robust infrastructure and a mature regulatory environment. The United States, in particular, benefits from a dense network of cyclotron and reactor facilities, with major players such as Curium and Lantheus spearheading the production of key isotopes like technetium-99m and fluorine-18. Canada’s Nordion continues to be a significant supplier of cobalt-60 and other medical isotopes. The region is also witnessing increased investment in next-generation isotopes, such as actinium-225, with public-private partnerships aiming to secure domestic supply chains and reduce reliance on foreign sources.

Europe is characterized by a collaborative approach, with cross-border initiatives and centralized production hubs. The region’s regulatory harmonization under the European Medicines Agency facilitates streamlined approvals and distribution. Companies like Eckert & Ziegler in Germany and IBA in Belgium are expanding their radiopharmaceutical portfolios, focusing on both established and emerging isotopes. The European Union’s investment in research infrastructure, such as the European Isotope Separation On-Line (ISOL) facilities, is expected to bolster the continent’s capacity for novel isotope development and clinical translation.

Asia-Pacific is experiencing the fastest growth, driven by rising healthcare demand and government support for nuclear medicine. Japan’s Sumitomo Chemical and South Korea’s KIRAMS are notable for their investments in cyclotron technology and radiopharmaceutical manufacturing. China is rapidly scaling up its domestic production capabilities, with state-backed enterprises focusing on both diagnostic and therapeutic isotopes to meet the needs of its expanding healthcare system. Regional collaborations and technology transfers are expected to accelerate, particularly in the context of theranostics and personalized medicine.

Rest of World regions, including Latin America, the Middle East, and Africa, are gradually enhancing their radiopharmaceutical manufacturing capabilities. Brazil’s IPEN and South Africa’s NTP Radioisotopes are leading efforts to localize isotope production and reduce import dependency. These regions face challenges related to infrastructure and regulatory harmonization but are increasingly participating in international supply chains and clinical trials.

Looking ahead, global demand for half-life isotope radiopharmaceuticals is projected to rise, with regional strategies focusing on supply chain resilience, innovation in isotope production, and expanded clinical access. Strategic investments and cross-border collaborations will be critical in addressing both current and emerging healthcare needs.

Competitive Strategies and Partnership Developments

The competitive landscape of half-life isotope radiopharmaceuticals manufacturing in 2025 is characterized by strategic collaborations, vertical integration, and investments in advanced production technologies. As the demand for diagnostic and therapeutic radiopharmaceuticals grows—driven by the expansion of nuclear medicine and precision oncology—leading manufacturers are intensifying efforts to secure isotope supply chains and expand their global reach.

Major industry players such as Curium, Siemens Healthineers, and GE HealthCare are leveraging partnerships with cyclotron operators, academic institutions, and healthcare providers to ensure reliable access to short-lived isotopes like Fluorine-18, Gallium-68, and Technetium-99m. For example, Curium has expanded its European and North American production footprint through acquisitions and joint ventures, aiming to streamline logistics for isotopes with half-lives measured in hours. Similarly, Siemens Healthineers continues to invest in cyclotron and radiochemistry platform development, supporting decentralized production models that bring isotope manufacturing closer to end-users.

In 2025, supply chain resilience remains a top priority. Companies are forming alliances with nuclear reactors and cyclotron facilities to mitigate risks associated with single-source dependencies. Nordion, a key supplier of medical isotopes, has reinforced its partnerships with reactor operators to ensure a stable supply of Molybdenum-99, the precursor for Technetium-99m generators. Meanwhile, Eckert & Ziegler is expanding its radiopharmaceutical manufacturing capacity in Europe and North America, focusing on both established and emerging isotopes for theranostic applications.

Strategic investments in R&D and regulatory compliance are also shaping the competitive strategies of leading firms. Companies are collaborating with regulatory agencies and academic research centers to accelerate the approval and commercialization of novel radiopharmaceuticals. For instance, GE HealthCare is actively involved in public-private partnerships to develop next-generation PET tracers and targeted radiotherapeutics, aiming to address unmet clinical needs in oncology and neurology.

Looking ahead, the next few years are expected to see further consolidation, with manufacturers seeking to acquire or partner with specialized isotope producers and radiopharmacies. The trend toward decentralized, on-demand isotope production—enabled by compact cyclotrons and automated synthesis modules—will likely intensify, fostering new alliances between technology providers and healthcare networks. As regulatory frameworks evolve to accommodate innovative radiopharmaceuticals, competitive strategies will increasingly hinge on agility, supply chain integration, and collaborative innovation.

Future Outlook: Disruptive Technologies and Market Opportunities

The landscape of half-life isotope radiopharmaceuticals manufacturing is poised for significant transformation in 2025 and the coming years, driven by disruptive technologies and emerging market opportunities. The sector is experiencing a surge in demand for both diagnostic and therapeutic radiopharmaceuticals, particularly those utilizing short-lived isotopes such as Fluorine-18, Gallium-68, and Lutetium-177. This demand is catalyzing innovation in isotope production, supply chain logistics, and regulatory frameworks.

One of the most notable technological advancements is the increasing adoption of automated and decentralized cyclotron systems. Companies like GE HealthCare and Siemens Healthineers are investing in compact cyclotron technologies that enable on-site or near-site production of short half-life isotopes, reducing reliance on centralized manufacturing and mitigating logistical challenges associated with rapid decay. This shift is expected to enhance the availability of PET tracers and other radiopharmaceuticals, especially in regions previously underserved due to transportation constraints.

Another disruptive trend is the development of advanced targetry and radiochemistry modules, which improve isotope yield and purity. Eckert & Ziegler, a leading supplier of radiopharmaceutical components, is expanding its portfolio to include next-generation synthesis units and automated dispensing systems, streamlining the production process and ensuring compliance with stringent regulatory standards.

Theranostics—a field combining diagnostic imaging and targeted radionuclide therapy—is emerging as a major market opportunity. The use of isotopes like Lutetium-177 and Actinium-225 for personalized cancer treatment is gaining traction, with companies such as Nordion and Curium scaling up production capabilities to meet anticipated clinical demand. These developments are supported by ongoing investments in isotope enrichment and generator technologies, which are critical for the reliable supply of therapeutic isotopes.

Looking ahead, the integration of artificial intelligence and digital twin technologies into manufacturing workflows is expected to optimize process control, predictive maintenance, and quality assurance. This digital transformation, championed by industry leaders, will likely accelerate time-to-market for new radiopharmaceuticals and improve scalability.

In summary, the future of half-life isotope radiopharmaceuticals manufacturing is characterized by decentralization, automation, and the convergence of diagnostics and therapeutics. As regulatory agencies adapt to these innovations and global healthcare systems increasingly adopt precision medicine, the sector is well-positioned for robust growth and expanded patient access in 2025 and beyond.