Table of Contents

- Executive Summary: 2025 Snapshot & Key Findings

- Market Size & Forecast: Monkfruit Enzyme Extraction (2025–2030)

- Technology Overview: Enzyme Extraction Methods and Innovations

- Raw Material Sourcing and Sustainable Supply Chains

- Major Players & Company Strategies (with Official Website Links)

- Regulatory Landscape & Compliance Standards

- Cost Analysis: Operational Efficiency and Scale-Up Challenges

- Emerging Applications: Food, Beverage, and Beyond

- R&D Pipelines: Next-Gen Enzyme Solutions

- Future Outlook: Disruptive Trends and Strategic Opportunities (2025–2030)

- Sources & References

Executive Summary: 2025 Snapshot & Key Findings

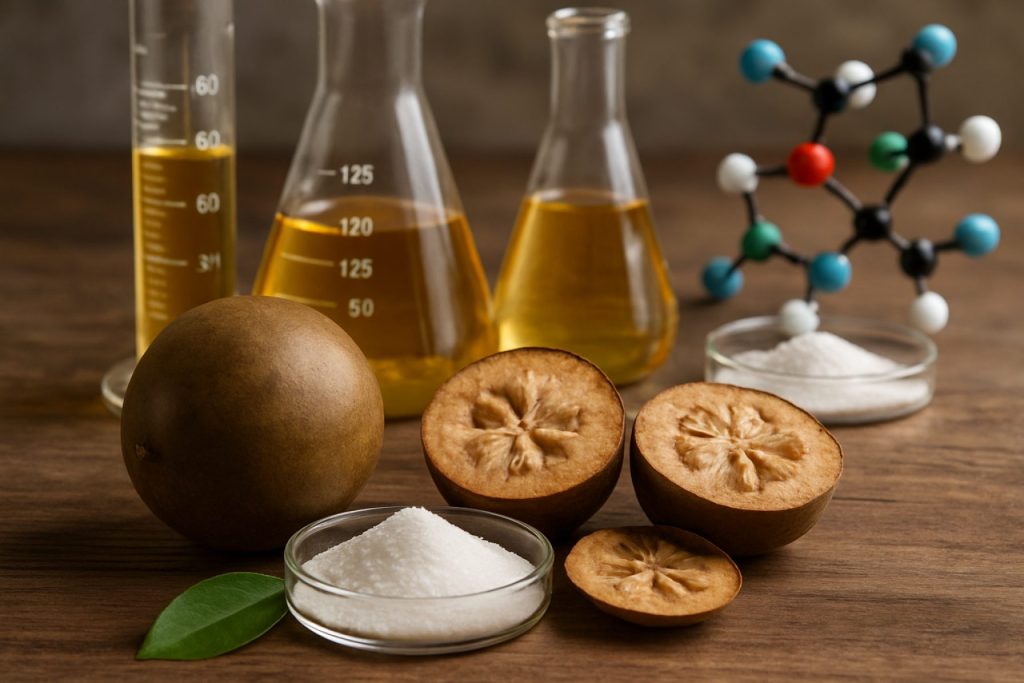

The global landscape of monkfruit enzyme extraction technologies is undergoing rapid transformation as demand for natural, high-intensity sweeteners surges in 2025. Monkfruit (Siraitia grosvenorii), prized for its mogroside V content, has become central to product innovation across food and beverage sectors. Extraction techniques are evolving to enhance yield, purity, and sustainability—critical factors as end-users and regulators prioritize clean-label ingredients and environmental stewardship.

In 2025, leading producers have focused on optimizing enzymatic hydrolysis methods, which improve the selective extraction of mogrosides while minimizing unwanted byproducts. This year, companies such as Guilin Layn Natural Ingredients Corp. and Guilin Yongxin Biotechnology Co., Ltd. have invested in proprietary enzyme blends and tailored biocatalytic processes that significantly boost extraction efficiency and product consistency. These developments allow for higher yields of sweet mogrosides, reduced energy and solvent usage, and scalability to meet increasing market demand.

Current data indicates that enzyme-aided extraction can result in a 10–20% improvement in mogroside V recovery compared to traditional solvent or water extraction. Additionally, enzyme technologies enable lower operational temperatures and shorter extraction cycles, aligning with sustainability goals by reducing energy consumption and greenhouse gas emissions. For instance, Layn Natural Ingredients reports the deployment of integrated enzyme-assisted extraction and purification systems at its facilities, targeting both efficiency and environmental responsibility.

Looking ahead, technological advancements are expected to further drive adoption. With ongoing investment in research and development, companies are exploring the use of immobilized enzymes and continuous flow bioreactors to enable even more efficient and scalable processes. Partnerships between extraction technology firms and agricultural cooperatives in Guangxi and Hunan provinces—the primary monkfruit growing regions—are anticipated to strengthen supply chain resilience and promote responsible sourcing.

The outlook for the next few years suggests continued growth in enzyme-based extraction, propelled by regulatory support for natural sweeteners and rising consumer awareness. As proprietary technologies mature, industry leaders are poised to set new benchmarks for extraction yield, cost-effectiveness, and environmental performance. The convergence of biotechnology and process engineering is expected to solidify monkfruit’s status as a sustainable, mainstream sweetener for global markets.

Market Size & Forecast: Monkfruit Enzyme Extraction (2025–2030)

The global market for monkfruit enzyme extraction technologies is poised for robust growth from 2025 through 2030, propelled by increasing consumer demand for natural sweeteners and advancements in bioprocessing. As food and beverage manufacturers pivot toward clean-label and sugar-reduction solutions, monkfruit (Siraitia grosvenorii) extracts—particularly mogrosides—are in high demand. This has driven innovation in enzyme-assisted extraction, which offers efficiency and sustainability benefits over traditional methods.

In 2025, leading monkfruit producers such as Guilin Layn Natural Ingredients Corp. and NutraMonk are investing heavily in enzyme extraction technologies. These processes utilize food-grade enzymes to selectively hydrolyze cell wall polysaccharides, significantly increasing mogroside yields while reducing solvent use and processing times. According to Layn Natural Ingredients, enzymatic extraction can improve product purity and decrease environmental impact, aligning with sustainability goals set by major ingredient suppliers.

Technological advancements are also being driven by partnerships between extraction technology providers and bioprocessing equipment manufacturers. For example, GEA Group supplies scalable bioprocessing solutions tailored for enzyme-based extraction, enabling commercial producers to expand capacity in response to global demand. In parallel, Cargill is involved in the development and commercialization of monkfruit sweeteners, further validating sector growth and the adoption of advanced extraction methods.

Market outlook for 2025–2030 is optimistic. Industry stakeholders anticipate double-digit annual growth rates, with large-scale investments targeting both upstream raw material supply and downstream processing efficiency. The expansion of monkfruit cultivation in China and Southeast Asia ensures a stable supply chain, while technology licensing and joint ventures are making enzyme extraction accessible to new entrants in North America and Europe (Layn Natural Ingredients). Furthermore, regulatory approvals for monkfruit extracts in key markets—such as the United States, European Union, and Australia—are expected to accelerate the adoption of these technologies in mainstream food and beverage applications.

- By 2030, enzyme-based extraction is projected to become the industry standard for premium monkfruit sweetener production.

- Leading players are integrating digitalization and process automation to optimize yields and ensure product consistency (GEA Group).

- Continued R&D and global partnerships will likely drive down production costs, further expanding market accessibility and end-user adoption.

Technology Overview: Enzyme Extraction Methods and Innovations

Monkfruit (Siraitia grosvenorii) has gained considerable traction as a natural, zero-calorie sweetener, primarily due to its mogroside content. Efficient and sustainable extraction of these mogrosides—especially at industrial scale—relies heavily on advancements in enzyme-assisted extraction (EAE) technologies. Over the past few years and moving into 2025, several companies and research institutions have intensified efforts to optimize these methods, aiming to enhance yields, purity, and environmental sustainability.

Currently, enzyme extraction of monkfruit involves the use of specific enzymatic cocktails, such as cellulases, pectinases, and hemicellulases, to break down cell walls and facilitate the release of mogrosides. Recent process optimizations focus on adjusting pH, temperature, and enzyme concentrations in order to maximize recovery while minimizing degradation of sensitive glycosides. In 2023–2024, companies like Layn Natural Ingredients expanded their application of proprietary enzyme blends, reporting improved extraction efficiency and scalability for food and beverage clients.

Technological innovation is also evident in the adoption of immobilized enzyme systems. These systems enable the reuse of enzymes across multiple extraction cycles, reducing operational costs and environmental impact. Pilot programs by Guilin Liangjiang Biology Technology are exploring immobilized cellulase/pectinase matrices, with early data suggesting a 15–20% increase in yield compared to traditional batch processes.

Additionally, process integration with physical technologies—such as ultrasound-assisted enzyme extraction (UAEE)—is gaining attention. This hybrid approach, under investigation by EcoGreen Fine Chemicals, uses ultrasonic waves to disrupt plant matrices, synergizing with enzymatic hydrolysis to speed up extraction and improve mogroside content. Early-stage results in 2024 show extraction times reduced by up to 40% without compromising mogroside purity.

Looking ahead to 2025 and beyond, the sector anticipates further advances in enzyme engineering, including the development of monkfruit-specific glycosidases that selectively enhance mogroside-V production while diminishing off-flavors. Several patent filings from Guilin Yifang Technology indicate ongoing investment in custom enzyme design and process automation for large-scale, high-purity monkfruit extracts.

With consumer demand for natural sweeteners continuing to rise, these enzyme extraction innovations are poised to deliver not only superior products but also more sustainable and cost-efficient production models for the monkfruit industry in the coming years.

Raw Material Sourcing and Sustainable Supply Chains

The extraction of high-purity mogrosides from monkfruit (Siraitia grosvenorii) relies heavily on advanced enzyme extraction technologies, which are rapidly evolving to address both efficiency and sustainability concerns entering 2025. As global demand for natural, zero-calorie sweeteners continues to rise, particularly in North America and Europe, monkfruit processors are under increasing pressure to optimize raw material use while minimizing environmental impact.

A central development in 2024-2025 is the scaling of tailored enzyme blends that target the β-glucosidic bonds in monkfruit pulp, significantly improving the yield and purity of mogroside V—the compound most sought after for its intense sweetness and clean flavor profile. Industry leaders such as Layn Natural Ingredients have invested in proprietary enzymatic hydrolysis methods, replacing traditional solvent-based extractions, thereby reducing both chemical waste and water consumption. This shift is also supported by upstream investments in vertically integrated supply chains, with Guilin GFS Monk Fruit Corp. enhancing traceability and quality control from farm to extraction facility.

The adoption of enzyme-assisted extraction also dovetails with sustainability goals. Enzyme technologies operate at lower temperatures and pressures, resulting in lower energy use and a reduced carbon footprint compared to conventional methods. Furthermore, by maximizing mogroside recovery from each fruit, these processes decrease agricultural waste, aligning with circular economy principles—a key criterion for major food and beverage multinationals sourcing monkfruit extracts. For example, Ingredi collaborates directly with growers to ensure responsible sourcing, supporting both the livelihoods of smallholder farmers in Guangxi and the long-term preservation of monkfruit biodiversity.

Looking forward to the next few years, industry participants anticipate further optimization of enzyme formulations, potentially through the integration of biotechnology and precision fermentation. This could enable the selective amplification of desired mogroside isoforms and create new value-added co-products from monkfruit biomass. Regulatory frameworks in key markets are also expected to evolve, with stricter requirements for traceability and environmental stewardship, prompting companies to invest in digital supply chain solutions and transparent sourcing practices.

Overall, the convergence of enzyme extraction innovation and sustainable sourcing is set to define the monkfruit sector through 2025 and beyond, as stakeholders prioritize both product quality and responsible production to meet global demand.

Major Players & Company Strategies (with Official Website Links)

The monkfruit enzyme extraction sector has seen notable activity in 2025, with several major players investing in technology upgrades, capacity expansion, and strategic collaborations to optimize the extraction of mogrosides—the key sweet components in monkfruit. Companies are leveraging advanced enzymatic processes to improve yield, purity, and sustainability of extraction, addressing both rising consumer demand and regulatory expectations for natural sweeteners.

- Layn Natural Ingredients: As one of the world’s largest monkfruit extract producers, Layn Natural Ingredients continues to invest in proprietary enzyme-assisted extraction platforms. In 2025, Layn expanded its R&D center in Guangxi, China, focusing on optimizing enzyme cocktails to boost mogroside V content while minimizing unwanted compounds. The company reports improved extraction efficiency and reduced solvent usage, supporting both cost reduction and sustainability goals.

- Guilin GFS Monk Fruit Corp: Guilin GFS Monk Fruit Corp has established itself as a pioneer in enzyme-based extraction. Throughout 2025, GFS has collaborated with global F&B partners to tailor its enzymatic processes for specific food applications, enhancing flavor profiles and solubility of monkfruit extracts. The company is investing in continuous process monitoring and enzyme optimization to ensure consistent quality, which has helped expand its export footprint.

- Biovittoria Limited: Operating out of New Zealand and China, Biovittoria Limited has focused on refining its multi-enzyme extraction protocols. In 2025, the company announced a partnership with specialty enzyme manufacturers to co-develop novel enzyme blends targeting improved mogroside selectivity. Their strategy emphasizes non-GMO, sustainable solutions, and they are actively scaling up pilot projects for commercial rollout in 2026.

- Ingredion Incorporated: Ingredion Incorporated has accelerated its investment in monkfruit extraction technologies since its acquisition of PureCircle. In 2025, Ingredion expanded its enzyme-assisted monkfruit extraction lines at its Malaysian facility, focusing on process automation and digital quality controls. The company is marketing its monkfruit sweeteners as clean-label, traceable, and tailored for global beverage and dairy brands.

Looking ahead, the competitive landscape is expected to intensify as companies pursue patentable enzyme systems, scale up green extraction technologies, and form global alliances to secure monkfruit supply chains. Strategic focus on process sustainability and product customization will likely shape new partnerships and innovations through 2026 and beyond.

Regulatory Landscape & Compliance Standards

The regulatory landscape for monkfruit enzyme extraction technologies is rapidly evolving, as global demand for natural, high-intensity sweeteners accelerates. In 2025, regulatory scrutiny is particularly focused on the methods and purity of extracts, as well as the source and handling of enzymes—often genetically engineered or produced through microbial fermentation. Major regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) require rigorous documentation and approval procedures for both the extraction enzymes and the final monkfruit-derived products.

In the United States, monkfruit (Luo Han Guo) extracts produced via enzymatic hydrolysis or biotransformation must demonstrate safety and consistency. Companies like Layn Natural Ingredients have obtained Generally Recognized as Safe (GRAS) status for their enzymatic extraction methods, providing transparency on enzyme sources and processing conditions. The FDA’s GRAS notifications demand comprehensive data on enzyme origin—often recombinant strains of Aspergillus niger or Trichoderma reesei—and the absence of residual DNA or allergenic proteins in the final extract.

In Europe, EFSA’s Novel Food regulations classify enzymatically-extracted monkfruit glycosides as novel ingredients, requiring premarket authorization. Producers must submit detailed dossiers covering enzyme production, residuals, and toxicological data. Companies such as Guilin Layn Natural Ingredients Corp. and INNOBIO are among those actively engaging with EU regulatory processes to ensure their enzyme-aided extracts comply with these rigorous standards.

- Enzyme Source Disclosure: Full traceability of enzyme production is required, including disclosure if enzymes are derived from genetically modified organisms (GMOs). This is critical for both U.S. and EU compliance.

- Process Validation: Manufacturers must validate that their enzyme extraction process consistently produces high-purity mogroside V (the primary sweet component) and minimizes contaminants or by-products.

- Labeling and Allergen Management: Any potential allergenic risks from microbial or recombinant enzymes must be addressed through testing and transparent labeling.

Looking ahead, as enzymatic extraction technologies become increasingly sophisticated—enabling higher yields and purer isolates—regulators are expected to update safety assessment protocols and introduce more harmonized global standards. Industry leaders such as Layn Natural Ingredients and Guilin Layn Natural Ingredients Corp. are proactively collaborating with authorities, aiming to set best practices and facilitate smoother international trade in monkfruit extracts. The next few years will likely see the introduction of specific enzyme-use guidelines and digital traceability requirements, driven by both safety considerations and consumer demand for transparency.

Cost Analysis: Operational Efficiency and Scale-Up Challenges

Monkfruit (Siraitia grosvenorii) enzyme extraction technologies have seen significant advancements as demand for natural sweeteners accelerates globally. In 2025, operational efficiency and cost competitiveness remain central challenges, particularly as manufacturers seek to scale up from pilot to commercial production. The shift from traditional solvent-based extraction to enzyme-assisted processes has been instrumental in improving yields and purity of mogrosides—the key sweetening compounds—while reducing solvent usage and environmental impact.

Operational costs in enzyme extraction are influenced by several factors, including raw material quality, enzyme procurement, process optimization, and downstream purification. Leading manufacturers such as Guilin Layn Natural Ingredients Corp. and Guilin GFS Monk Fruit Corp. have invested in proprietary enzyme blends and bioreactor systems to maximize mogroside yields while lowering energy and labor inputs. However, enzyme costs remain significant, accounting for up to 20% of total extraction expenditures. Companies are increasingly partnering with enzyme specialists to develop more robust and recyclable biocatalysts, aiming to reduce per-batch enzyme consumption and extend catalyst lifespans.

Scale-up poses unique challenges, as laboratory successes do not always translate linearly to industrial scale. Maintaining enzyme activity and process consistency in larger reactors requires precise control of pH, temperature, and substrate concentration. Both Layn and GFS Monk Fruit have reported increased capital expenditure during scale-up phases, particularly related to bioreactor design and aseptic handling systems. Process bottlenecks often occur during filtration and purification, where increased volume can lead to reduced throughput and higher operational costs.

Looking ahead, automation and digitization are expected to drive further efficiencies. Companies are deploying real-time monitoring and process analytics to optimize enzyme dosages and extraction times, thereby reducing waste and improving batch consistency. The integration of membrane filtration and chromatographic systems is another trend aimed at enhancing product recovery and purity at scale. Despite these advancements, the high initial capital outlay and recurring enzyme costs remain barriers for new entrants, suggesting that only firms with significant R&D resources and established supply chains—such as Layn Natural Ingredients—will be able to maintain cost leadership in the near term.

In summary, while enzyme extraction technologies are improving operational efficiency for monkfruit processing in 2025, overcoming scale-up challenges and controlling costs will require continued innovation, strategic supplier partnerships, and capital investment by industry leaders.

Emerging Applications: Food, Beverage, and Beyond

Monkfruit (Siraitia grosvenorii), prized for its natural, zero-calorie sweetness derived mainly from mogrosides, has seen surging demand as consumers increasingly seek plant-based sugar alternatives. In 2025 and the upcoming years, technologies for extracting these sweet compounds—particularly enzymatic extraction—are rapidly evolving to enhance efficiency, purity, and sustainability, directly impacting food, beverage, and other applications.

Traditional extraction methods often relied on solvent-based processes that could leave residues and degrade sensitive mogrosides. In contrast, enzyme-assisted extraction leverages specific cellulases, pectinases, and other hydrolytic enzymes to break down monkfruit cell walls, releasing mogrosides more gently and efficiently. This not only increases yield but also preserves the molecular integrity of the sweeteners, resulting in a cleaner taste profile and broader application in premium food and beverage products.

Key industry players are scaling up the adoption of enzyme-assisted extraction. Layn Natural Ingredients, one of the world’s largest monkfruit ingredient producers, has prioritized enzymatic extraction in their proprietary processes, citing improved purity and reduced energy consumption as core advantages. Similarly, Guilin Lvjian Bio-Engineering Co., Ltd. has invested in continuous research and development to optimize enzyme selection and processing parameters for higher mogroside V content, the primary sweetening compound.

Several companies are also focusing on process integration and automation. For example, Guilin Yongfu Monk Fruit Co., Ltd. reports that integrating enzymatic extraction with advanced membrane filtration has significantly lowered the environmental footprint of their production lines while delivering monkfruit extracts suitable for a wider range of finished products, from beverages to pharmaceuticals.

Looking ahead, enzyme-assisted extraction is expected to underpin further innovations beyond foods and drinks. Companies are exploring the application of high-purity monkfruit extracts in nutraceuticals, oral care, and even as natural excipients in pharmaceuticals. As consumer and regulatory pressures mount for clean-label products, enzymatic technologies offer a sustainable pathway, minimizing chemical residues and waste.

With continued investment in enzyme engineering and process optimization, the outlook for monkfruit enzyme extraction technologies remains robust through 2025 and beyond. As industry leaders such as Layn Natural Ingredients and Guilin Lvjian Bio-Engineering Co., Ltd. push the boundaries of purity, efficiency, and sustainability, monkfruit is poised to expand well beyond its current stronghold in food and beverage, ushering in new applications in health and wellness markets.

R&D Pipelines: Next-Gen Enzyme Solutions

In 2025, the landscape of monkfruit enzyme extraction technologies is marked by rapid advancements driven by both established ingredient manufacturers and emergent biotech firms. The demand for cleaner, more efficient extraction methods stems from the need to obtain high-purity mogrosides—especially mogroside V, the principal sweet component—while reducing solvent usage, process time, and environmental impact.

A primary trend in current R&D pipelines is the refinement of enzymatic hydrolysis techniques. Unlike traditional solvent extraction, enzyme-assisted methods offer greater specificity and lower degradation of bioactive compounds. For instance, Layn Natural Ingredients has developed proprietary enzyme cocktails that target the cell wall matrix of monkfruit, facilitating the release of mogrosides under mild conditions. Their recent updates indicate pilot-scale success in using recombinant glycosidases to boost yield and purity, achieving over 95% mogroside V content in extract streams.

Meanwhile, Guilin Biotechnological Research Institute, a key player in China’s monkfruit industry, is investing in enzyme immobilization technologies for repeated batch processing. Immobilized enzyme reactors are being tested to improve operational stability and reduce costs associated with enzyme turnover—an important consideration for large-scale production expected to ramp up by 2026.

Another notable direction is the integration of process analytical technologies (PAT) to monitor and optimize enzyme reactions in real time. AMG Group, which specializes in plant extraction solutions, has introduced inline spectroscopy and biosensor modules into their monkfruit extraction lines. These systems enable precise control of reaction endpoints, ensuring consistent product quality and minimizing over-processing.

Looking ahead to the next few years, the R&D focus is likely to expand into enzyme engineering—tailoring enzyme specificity for novel mogroside glycosides with improved sweetness profiles and taste modulation effects. Collaborative projects between ingredient producers and enzyme technology companies, such as ongoing work by Novozymes in enzyme discovery for natural sweetener production, are anticipated to yield next-generation biocatalysts optimized for monkfruit substrates.

In summary, the current and near-future R&D pipelines in monkfruit enzyme extraction technologies center on improving enzyme efficiency, process sustainability, and product quality, with a strong outlook for commercialization of advanced enzymatic processes by leading manufacturers in the sector.

Future Outlook: Disruptive Trends and Strategic Opportunities (2025–2030)

Between 2025 and 2030, monkfruit enzyme extraction technologies are poised for significant advancements, driven by both consumer demand for natural sweeteners and industry efforts to achieve higher purity, sustainability, and cost-efficiency. Several trends are expected to define the sector’s trajectory in the near term.

Firstly, leading manufacturers are accelerating the adoption of enzyme-assisted extraction to enhance the yield of mogrosides—the intensely sweet compounds in monkfruit. By leveraging proprietary enzyme cocktails, companies such as Layn Natural Ingredients have reported notable improvements in extraction efficiency and reduction of undesired plant flavors. This approach enables the selective conversion of precursor compounds into the more desirable mogroside V, increasing both potency and product consistency.

In addition, continuous bioprocessing and membrane filtration technologies are being integrated into extraction lines to further streamline purification and reduce water and energy consumption. For instance, Guilin Lvjian Bioengineering has invested in automated membrane systems that allow for scalable separation of mogrosides with minimal solvent use. Such process intensification is expected to become a standard across the industry, aligning with global sustainability goals.

Looking ahead, synthetic biology is emerging as a potentially disruptive force in monkfruit sweetener production. Companies including Ingredion are exploring enzyme engineering and microbial fermentation platforms to biosynthesize mogrosides in controlled environments, bypassing agricultural constraints and further reducing resource inputs. While full commercialization of these technologies may take several years, pilot-scale successes have already been demonstrated, suggesting a shift toward precision fermentation is on the horizon.

The strategic opportunities for stakeholders in this evolving landscape are significant. Ingredient suppliers are expected to form new partnerships with enzyme developers and bioprocessing equipment manufacturers to access cutting-edge capabilities. Furthermore, as regulatory frameworks adapt to novel production methods, early movers will likely capture premium market share by offering traceable, label-friendly monkfruit extracts tailored to the needs of food and beverage brands.

In summary, the period between 2025 and 2030 will likely see monkfruit enzyme extraction technologies transition from traditional solvent-based processes to highly efficient, enzyme-driven, and potentially fermentation-based platforms. The result will be a more sustainable, scalable, and versatile supply of monkfruit sweeteners, unlocking new product applications and global market expansion.